NOUVELLES

What are packaging principles of the horizontal stand up pouch packing machine ?

2025-03-12

What is a horizontal doypack sachet packing machine ?

This machine can package various materials including liquids, powders, granules, pastes, sauces, etc. The bag shapes are ordinary stand-up bags, special-shaped bags, hanging hole bags, zipper bags, etc. It is mainly suitable for food, daily chemicals, medicine, agrochemicals and other industries

https://www.grepack.com/news_xx/What_is_a_horizontal_doypack_bag_packing_machine_-.html

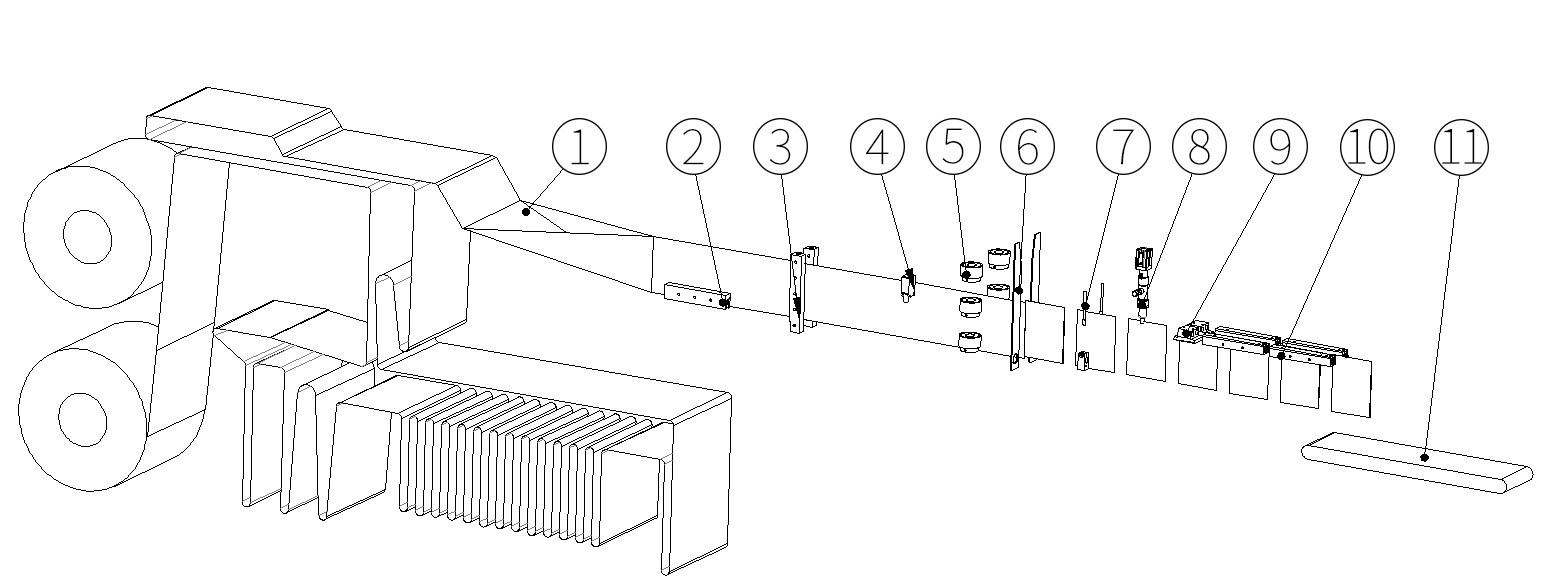

What are packaging principles of the horizontal stand up pouch packing machine ?

1, Bag forming

The forming station is the critical workstation responsible for shaping the packaging bags. As the packaging film passes through the former, it is molded into predetermined bag configurations, such as stand-up pouches, three-side seal bags, or four-side seal bags.

2, Bottom seal

The bottom sealing station is responsible for heat-sealing the bottom of the formed packaging bags, creating the bottom seal of the bags to provide a closed space for subsequent filling of materials.

3, Vertical seal

The vertical sealing station is responsible for heat-sealing the longitudinal edges of the packaging film, forming the side seals of the bags, further refining the shape of the packaging bags, and ensuring their tightness.

4, Photo cell

The photoelectric detection station uses photoelectric sensors to detect color marks or labels on the packaging film, enabling precise positioning and cutting of the packaging bags. This ensures that the pattern on each packaging bag is complete and accurately positioned.

5, Servo advance

The servo bag pulling station is the core station for controlling the conveying of the packaging film and the accuracy of the bag length. The servo motor drives the traction mechanism to precisely pull the packaging film forward according to the set bag length parameters.

6, Cutting

The cutting station: cutting the continuously delivered packaging film into individual bags. The cutting position is typically controlled with precision by photoelectric detection signals or a servo control system, ensuring cutting accuracy and consistency in bag width.

7, Pouch opening

The bag opening detection station is used to detect whether the packaging bag has been successfully opened. If it is detected that the bag has not been opened or has not been fully opened, the system will send out a signal to stop the filling process or trigger an alarm to prevent material leakage and equipment failures.

8, Filling

The filling station: filling a predetermined amount of products into the opened bags accurately. According to the shape and characteristics of the packaged products, the filling methods include liquid pumps, screw pump, volumetric cup, electronic scale, etc.

9, Pouch stretch

Before top sealing, the bag opening of the packaging bag is flattened to remove the wrinkles at the bag opening, in preparations for the subsequent high-quality sealing, and preventing situations such as unsealed areas or weak seals during the sealing process.

10, Heat top seal

First top sealing adopts heat-sealing way to melt the PE/ PET to intergrate two layer into one for finishing final sealing.

ensuring the sealing performance and freshness preservation of the product.

11, Outlet

The discharging station: convey the finished product, connecting to intelligent packaging system;

Mot clé :

DERNIÈRES NOUVELLES

2025-03-06